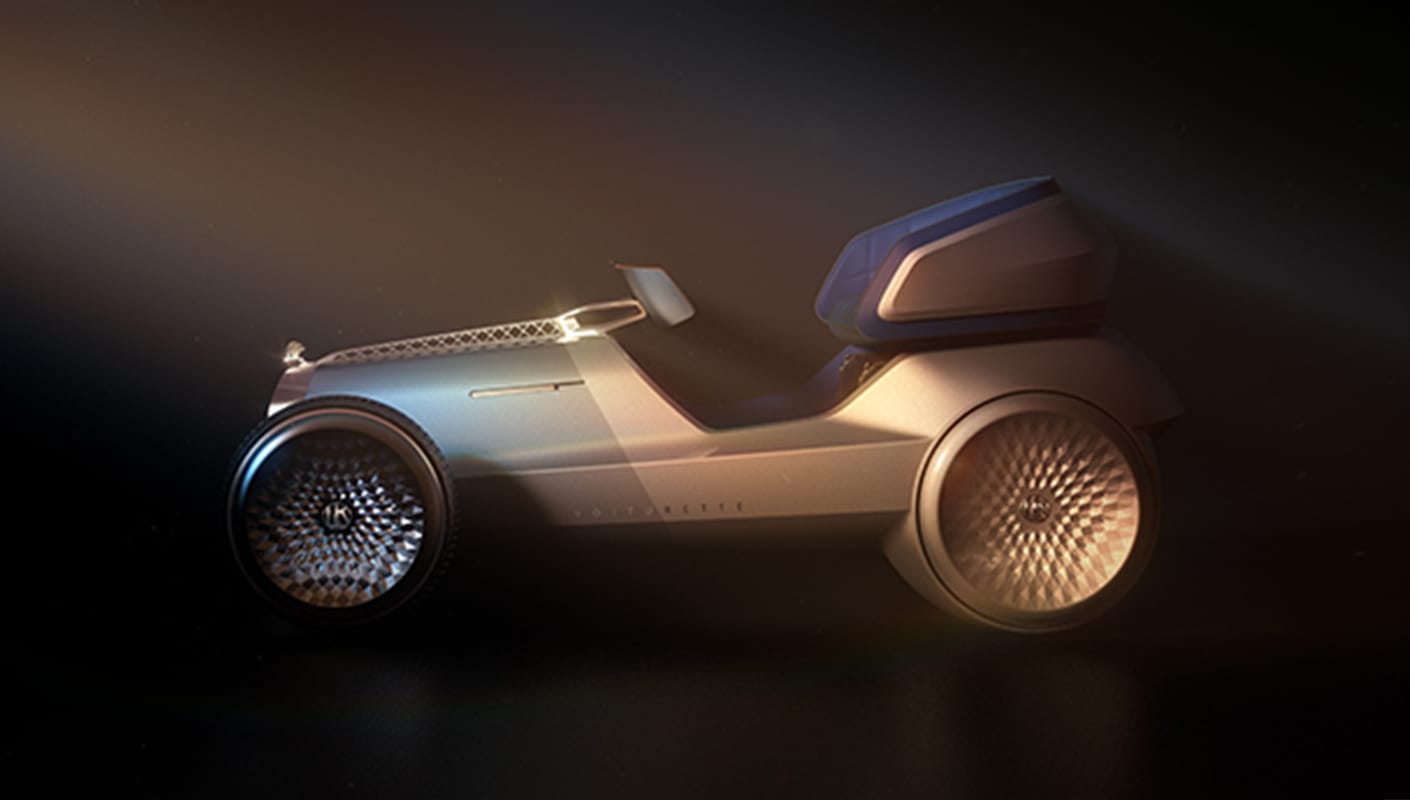

Post-production and CGI company PX Group is a master of visualizing the motor vehicle. It’s created imagery for fellow German companies Audi, Volkswagen, and Mercedes-Benz. You can immediately see why it’s become the visualization company of choice for such renowned companies: Its imagery quickly conveys the details — the texture of the dash, the grain of the leather seats, the glint of metallic flakes in the car paint. Exterior shots plant the cars in stylized realities; long-exposure cities for sports cars, and dusty trails for SUVs.

While the company also does other post-production and CGI work, for artist Oliver Kossatz working on automotive projects is the best part of the job. “I have a huge passion for cars, so of course they’re my favorite thing to render,” says Kossatz. “Of course we have lots of clients in other industries, so I am more of a generalist these days, rendering everything from products to architectural visualizations and animations.”

In the four years he’s worked for PX Group, Oliver has seen some dramatic changes in the way visualizations are made. While the automobile in the image has usually been a 3D creation, more and more clients ask for fully modelled environments such as cityscapes, modern buildings, or futuristic car parks. “V-Ray for 3ds Max, with its support for plugins such as Forest Pack, is a huge benefit for these jobs.”

While working on such a variety of projects could easily result in cookie-cutter images, PX Group’s imagery always looks unique and tailor-made for the project. The company works with the agency or client, who will either have a good idea of what they want, or who will be open to suggestions from Oliver and his team.

From here, Oliver models the scene, either from scratch, or cleaned up from CAD data if it’s provided. Next, he sets the camera and lights the scene, paying attention to anything the client wants to highlight. To ensure maximum realism, PX Group gets help from the experts.

“For vehicle renders, we often get lighting supervision by car photographers,” explains Oliver. “They have years of experience in shooting cars, and their input speeds up the lighting process dramatically. I like working with photographers because these projects are always fun and there is so much to learn from them.”

With the lighting and camera angles set, the images are sent to the clients for review. PX Group’s retouching team may also ask for images to be re-rendered, as this can be easier than fiddling with images in Photoshop. “A good relationship between CGI and post-production is a major part of our workflow,” says Oliver.

One challenge to Oliver’s workflow has been the detailed creation of materials for his projects. “In the past, we've relied on traditional workflows to capture diffuse, reflection and normal maps from photographs. The amount of time spent for putting this all together was very high, especially if you want to show every little detail.”

Oliver leaped at the chance to try VRscans, Chaos Group’s revolutionary library of high-quality scanned materials. The VRscans process photographs physical material thousands of times from different angles and under many lighting scenarios, resulting in a digital material which looks and acts exactly like the original.

VRscans has revolutionized our workflow. The library is very extensive and perfect for our kind of jobs. It’s exciting to see new materials being added all the time.

Oliver Kossatz, PX Group

“VRscans has revolutionized our workflow,” Oliver says.“The library that comes with VRScans is very extensive and perfect for our kind of jobs. It’s exciting to see new materials being added all the time.”

When suitable materials aren’t available in the VRscans library, a custom scanning service is available. Artists and designers can send physical samples, from 20 to 200 mm square, to Chaos Group, who will scan it into a seamless, tileable file. The scanned files are delivered via FTP, and the samples are returned. It’s a service Oliver has made use of.

“They turned out great!” he says. “They were samples we've had the most trouble with, like cloth for car interiors with very specific patterns. Using VRscans couldn't be easier, the process is foolproof as long as the geometry has properly assigned UV coordinates. This avoids common errors.”

With VRscans in place, Oliver is free to stop fiddling with materials and able to concentrate on the bigger picture. And while he’s not sure what his next image will be, it’s definitely going to be up his street. “The next project is always ahead,” he says. “It will be an automotive job, that's for sure.”