In this post, Edvinas from Studio 3D Architects, takes us through how they went about creating a whopping 40,000 product renders over a period of two years!

Beginnings

Hello all!

I am so excited to have a chance to share my experiences. In this post, I will cover something different from many tutorials and articles – I’ll be diving into the technical/organizational side of things, and looking at the tricks and techniques used when working on a big product rendering project. These techniques allowed our team to prepare more than 500 images per day at some points in the project. Of course, this couldn’t have been done without the simplicity of Corona!

Before starting, I would like to quickly introduce myself and my background.

I am Edvinas, an architect professionally, but an archviz artist at heart. I started my 3D career 12 years ago in Lithuania when I was 15 years old. I still don’t know how, but I was commissioned by a local real estate company when I was 16 years old. I think it was illegal at that time and they paid my parents instead of me!

Anyway, ever since then, I have never stopped working on various archviz projects around the world. Those years were so passionate! Just after my graduation in 2015, we (me, together with my partner who is now my wife) decided to start STUDIO 3D ARCHITECTS. Over 5 years, we tested ourselves with various archviz and product rendering projects, and one of them brings us to the main topic.

In 2016 we were commissioned by a furniture manufacturing company from New Zealand. Our task was to create 40,000 high-quality studio renders of 200 products, as well as prepare material and accessory libraries, together with realistic scene setups. Below, I will cover the most important discoveries we made during this project.

Material Library creation

At the very beginning, we received high-resolution photos of real wooden boards from the client. This isn’t the perfect method for creating a high-quality material library, but the deadlines were tough back in 2016 and we couldn’t travel to New Zealand. These days we always go to the factories and scan the boards ourselves.

Using Adobe Photoshop we converted these RAW files into seamless textures. Just as we finished creating those seamless textures, we received a pack of real wood samples with 24 coatings. These samples (30x20cm) were used to create physically accurate colors in 3ds Max and Corona.

We ended up with a multi-material consisting of 24 different colors and material IDs. Using the same method we also created wood-end, wood-drawers, stone and metal material libraries.

Accessories Library creation

Most of the products had handles, so we needed to create a library of those as well. We were happy to receive 3D files with correct measurements from the client, but unfortunately, these were not sufficient for high-end results. So we remodeled all of the 27 handles using poly modeling and then created custom materials. I have to mention that the Siger Studio library was a great base to start from when customizing metals.

The important part was to confirm the quality of the handle library with the client before we started rendering the products themselves. It would not have been good to render 40,000 images and then find out that some of the handles were incorrect! So we had a couple of rounds where we corrected the handles and other small details.

Rendering

The first part of the rendering stage required us to prepare a studio scene set up. After a few workshops and tests with the client, we ended up using a design featuring a concrete floor and white wall. This style was made to fit the new brand guidelines for our client’s company.

The second stage finally takes us to the process of product rendering! Here we found an effective way to render color variations of each product – I like to call it “simply powerful”. We used the native 3ds Max “material” modifier and animated it to switch the material ID on every frame. Doing it this way we only needed to do the animation work once. Afterward, we copied the same animated modifier onto the other products.

(Editor’s Note: In recent versions of Corona Renderer, the Corona Select Map and Select Material could be used to achieve similar results)

Automating the workflow

Renaming 40,000 files manually is not a good idea. Instead, we used free software called “Advanced Renamer” by Kim Jensen. If you use it commercially, please support the author!

As you may know, when you render an animation sequence in 3ds Max, all filenames have a suffix applied (001, 002, 003 etc.). This was extremely useful for us because using Advanced Renamer we could easily replace these suffixes with whatever wording we needed words. For example, a material with ID 9 was called “ash-clear-finish”. Using the software we could easily add a “replace” function which converts every single “009” in the filename into “ash-clear-ash” instead.

Using the same method we created functions for all 26 materials in 15 minutes. And then it only took us 20 seconds to rename 40,000 images. Easy!

Gallery

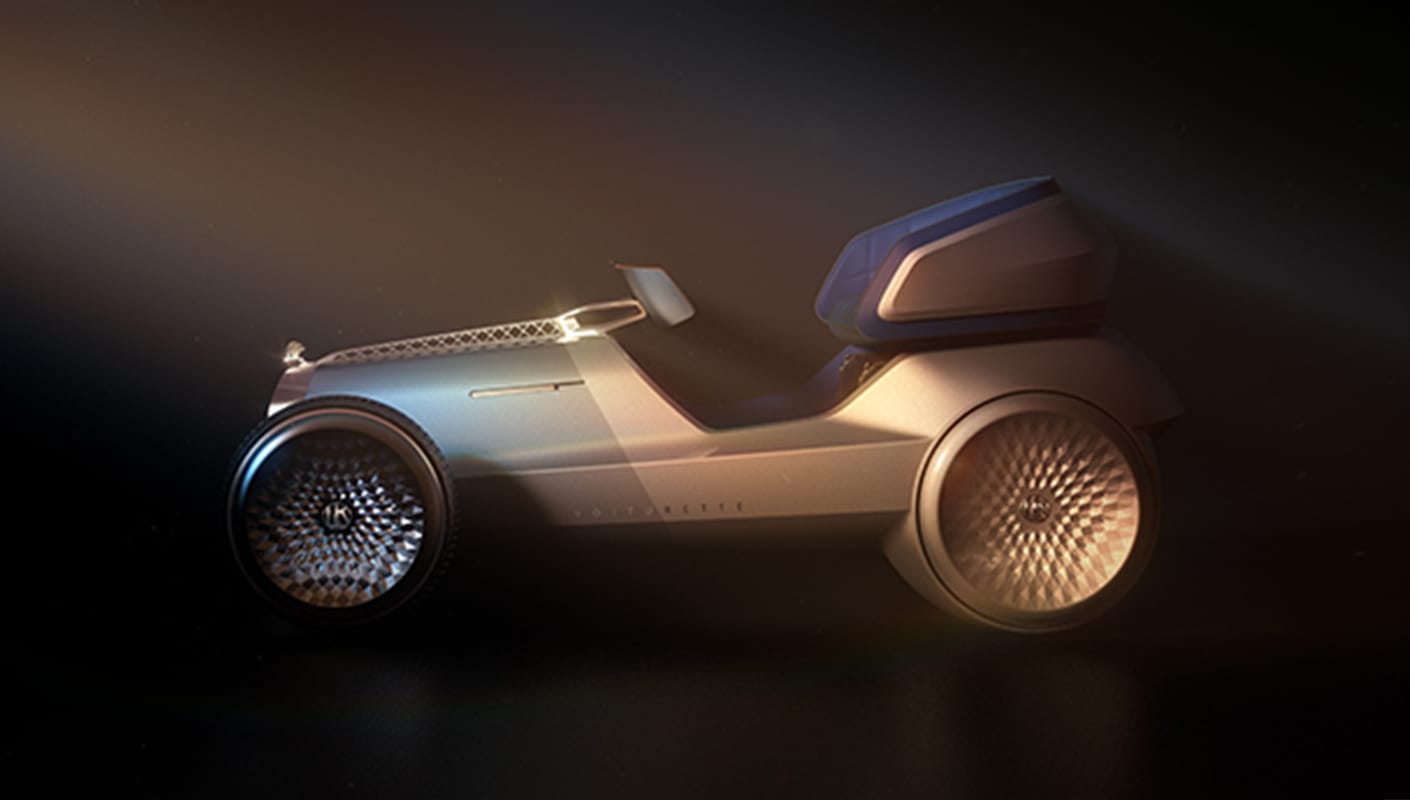

Over the two year period, not only did we create 250+ different products and 40,000 variation images, but we also created animations, and images of the products in place in a full scene. What is wonderful about Corona is that we do not even need to talk about it! It just works and lets us concentrate on creativity and project management. You can see some of our results below:

News & the future

Back in 2015, our commissioned projects gradually started to shift towards the luxury segment. We are extremely excited that so many great firms and designers value not only our work but also our consulting experience. This led us to a decision to represent our projects better and rebrand our company.

We plan to complete the transfer in 2020, and going forward we will call ourselves Bloorise.

Links

We post on IG constantly: https://www.instagram.com/bloorise.visual

From time to time I post on Behance: https://www.behance.net/3darchitect

You can also follow our FB page: https://www.facebook.com/bloorise

Website: https://studio3darchitects.com/

Rebrand Webiste: http://bloorise.com/